AEROSIL气相二氧化硅在热绝缘中应用

温室效应和全球变暖多年来一直是人们关注的重要问题。如何才能使这个重大的问题得以解决?

更广泛地利用可再生能源是解决问题的方法之一。另外,我们也可以降低能源的消耗,例如通过使用改良的保温材料。在欧洲,35%的主要能源被用于家庭。因此,在工业和运输方面,仍存在着巨大的节能潜力。良好的绝热性对于*大限度减少二氧化碳的排放量有一定的帮助。同时,在能源价格不断上涨的时下,它在降低成本方面也有显著的功效。

赢创开发的AEROSIL® 气相法二氧化硅,具备优越的绝热性能,非常低的导热系数,λ< 20 mW/m•K*。相比传统的隔热系统,比如聚苯乙烯或聚氨酯泡沫塑料、玻璃纤维或岩棉纤维,它具备更高的绝热性能。这些传统的绝缘材料的应用很多可以追溯到20世纪50年代。它们已经达到了其绝热性能的极限,不能满足当今高效保温的技术需求。这也是AEROSIL® 气相法二氧化硅越来越多地被用于高效保温系统解决方案中的原因。

降低能源消耗水平是减少二氧化碳排放量从而遏制全球变暖的关键所在。许多国家正通过立法大力推广这种生态模式——例如,更为严格的建筑法规或是对于家用电器引入节能效率分类的概念。

使用更好的保温材料能够通过降低能耗来显著地降低成本,面对当今不断上升的能源成本,投资高效的保温材料将很快实现成本的回收。

*) 与适合的遮光剂配合使用的效果

AEROSIL气相二氧化硅在热绝缘中应用-High-temperature insulation

AEROSIL® is already widely used as insulating material in ceramic stovetops, in industrial applications and in the field of fire protection.

Even when things get hot, Evonik offers the ideal solution. The heating elements underneath ceramic stove tops reach temperatures of up to 1,000 ºC — so they need insulation that can reliably stand up to the constant heat. Just another area in which AEROSIL® has proven itself as an insulating material.

A thin layer of AEROSIL® is built into the heating elements of many stovetops. Its insulating properties are so good that electrical wires can be located quite close to the heating elements themselves. But that’s not all. The layer of AEROSIL® also provides a reliable mount for the heating elements, which expand as they grow hot. This tried-and-proven application has been standard in many stovetops for decades now.

Its resistance to heat also makes AEROSIL® a reliable material for use in fire prevention and protection, where it is used in the making of elevator doors, airplane black boxes and to insulate pipes and conduits in chemical plants. AEROSIL® is an outstanding, low-weight, mineral-based insulator with excellent qualities, even at very high temperatures.

AEROSIL气相二氧化硅在热绝缘中应用-Vacuum-insulation panels (VIP)

AEROSIL® is used in vacuum-insulation panels (VIP) and has been in the spotlight for years as an essential component of energy-efficient refrigerators.

-

-.jpg)

- Vacuum-insulation panels (VIP)

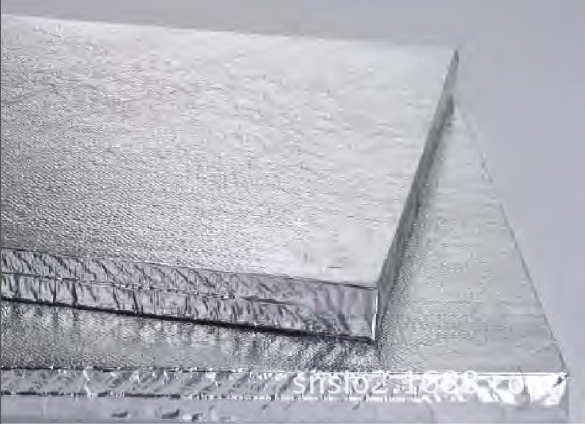

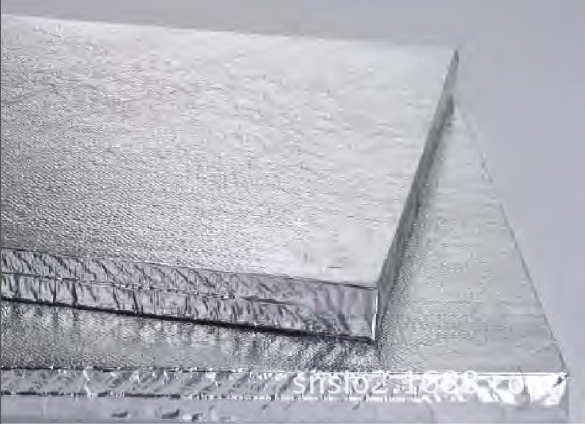

With the development of vacuum-insulation panels (VIP) 20 years ago, Evonik delivered a particularly energy-efficient and economical solution. The panels are made with vacuum-packed AEROSIL® encased in several layers of a special film that is impermeable to air and moisture. The better the quality of the structure of the silica in its core, the better the insulation effect of VIP. The way VIPs work is similar to a Thermos jug. The vacuum conducts very little heat, thereby inhibiting convection (the natural transfer of heat).

The success story of VIPs containing AEROSIL® began just a few years ago, when rapidly rising energy costs resulted in increased pressure to save energy. Although they are considerably thinner than conventional insulating materials, VIPs are about eight times as effective as the polyurethane foam previously used in refrigerators, for example.

In practical terms, that means a meaningful reduction in energy consumption as well as more space inside the refrigerator. Vacuum-insulation panels make it easy to manufacture refrigerators that achieve A++ and A+++ energy-efficiency ratings. Today, thanks to their reliability as insulating material, VIPs are also used in portable coolers like the ones used to transport blood samples, medicine, and human organs, where a constant temperature is of utmost importance.

Besides being a standard component of refrigerators and deep freezes, VIPs containing AEROSIL® are also used in a number of other areas, including packaging and containers for temperature-sensitive products as well as retrofit insulation for buildings, for example, exterior facades and floors. And cold transport trucks are also increasingly taking advantage of VIPs, which helps them reduce fuel consumption by up to 25 %. Thus new applications and new markets are opening up all the time.

AEROSIL气相二氧化硅在热绝缘中应用-冰箱真空隔热板

现代化冰箱需要具备充足的空间来存储所有的新鲜农产品、香浓奶酪、果汁以及各种各样的食品。此外,冰箱还必须节能。而这无疑给**品质的绝热材料提供了用武之地,以便结合其他因素,确保冰箱的节能性能。许多制造商选择基于AEROSIL®气相二氧化硅的真空隔热板(VIP),因为赢创工业集团生产的这种气相二氧化硅使得极薄的一层隔热材料便可获得优异的隔热性能。

电价一路飙升,日益上升的能源成本给许多家庭带来年复一年的资源压力。因此,节约能源已不再是仅仅出于生态考量的必要举措。做出上述变革性决定或许并非一件轻松的事情,但对新型节能电器进行投资的确能够持久且大幅地降低电力需求。事实证明,由于冰箱需要整年内时刻不停地保持运转,因而它的耗电量尤为巨大。根据德国联邦环境署的计算,能源效率等级为“A+++”的冰箱的耗电量甚至不到能源效率等级为“A”的老式冰箱的耗电量的一半。

为了实现上述能效等级,冰箱中所采用的隔热材料是一个决定性因素。如果采用传统隔热材料,则需要给冰箱安装非常厚的隔热层才能实现这种**的节能效果,;而这就意味着这类冰箱尺寸将会比厨房设计中所采用的标准规格要大。更重要的是,厚厚的隔热层将会减少冰箱内部储存新鲜食品的宝贵空间。

正因如此,人们才会专注于真空隔热板(VIP)的开发,以便将其用于冰箱制造,满足*高能效等级标准的要求。这一理念源于25年前,为当时宾馆房间内所用的小型冰箱的设计提供了推动力。其目标是为紧凑型冰箱设计尽可能大的存储空间。方案十分明显,即减少隔热材料的使用量。对此,赢创的专家提供了可行的解决方案:以AEROSIL®为填料的真空隔热板。作为性能优异的芯材,其结构特殊,这使得气相二氧化硅成为真空隔热材料中的**芯材。

**品质的薄层隔热材料

VIP的工作原理与双层保温外壳颇为相似。AEROSIL®材料被真空包装并密封在一个特殊的多层薄膜之中,薄膜具有**的气密性和防水性。真空状态令隔热性能本已很好的AEROSIL®的效率增强至五倍。这有效阻止了隔热材料中的热传导现象,即热量由热至冷的自然传导。保温容器能够防止过多热量向外部释放,而冰箱中的VIP则能够防止环境中的热量进入电器内部。二氧化硅实际上发挥着绝热体的作用,但同时也为隔热板提供保护,避免出现真空作用出现的凹陷。

**隔热材料

“芯材中二氧化硅结构的品质越好,VIP的隔热效果就越好,”赢创隔热应用技术部经理弗兰克•门泽尔(Frank Menzel)博士解释说。尽管VIP与传统隔热材料相比要薄得多,但是它能够达到约8至10倍的保温值。在实际应用中,这项性能意味着大幅减少能耗,同时增加冰箱内部的可利用空间。

因此,越来越多的冰箱组件供应商开始依靠AEROSIL®所带来的优异品质。其中一家供应商是Porextherm Dämmstoffe GmbH公司,它的总部设在肯普滕,十多年来一直从事VIP的生产。

AEROSIL气相二氧化硅在热绝缘中应用

现代化冰箱需要具备充足的空间来存储所有的新鲜农产品、香浓奶酪、果汁以及各种各样的食品。此外,冰箱还必须节能。而这无疑给**品质的绝热材料提供了用武之地,以便结合其他因素,确保冰箱的节能性能。许多制造商选择基于AEROSIL®气相二氧化硅的真空隔热板(VIP),因为赢创工业集团生产的这种气相二氧化硅使得极薄的一层隔热材料便可获得优异的隔热性能。

电价一路飙升,日益上升的能源成本给许多家庭带来年复一年的资源压力。因此,节约能源已不再是仅仅出于生态考量的必要举措。做出上述变革性决定或许并非一件轻松的事情,但对新型节能电器进行投资的确能够持久且大幅地降低电力需求。事实证明,由于冰箱需要整年内时刻不停地保持运转,因而它的耗电量尤为巨大。根据德国联邦环境署的计算,能源效率等级为“A+++”的冰箱的耗电量甚至不到能源效率等级为“A”的老式冰箱的耗电量的一半。

为了实现上述能效等级,冰箱中所采用的隔热材料是一个决定性因素。如果采用传统隔热材料,则需要给冰箱安装非常厚的隔热层才能实现这种**的节能效果,;而这就意味着这类冰箱尺寸将会比厨房设计中所采用的标准规格要大。更重要的是,厚厚的隔热层将会减少冰箱内部储存新鲜食品的宝贵空间。

正因如此,人们才会专注于真空隔热板(VIP)的开发,以便将其用于冰箱制造,满足*高能效等级标准的要求。这一理念源于25年前,为当时宾馆房间内所用的小型冰箱的设计提供了推动力。其目标是为紧凑型冰箱设计尽可能大的存储空间。方案十分明显,即减少隔热材料的使用量。对此,赢创的专家提供了可行的解决方案:以AEROSIL®为填料的真空隔热板。作为性能优异的芯材,其结构特殊,这使得气相二氧化硅成为真空隔热材料中的**芯材。

**品质的薄层隔热材料

VIP的工作原理与双层保温外壳颇为相似。AEROSIL®材料被真空包装并密封在一个特殊的多层薄膜之中,薄膜具有**的气密性和防水性。真空状态令隔热性能本已很好的AEROSIL®的效率增强至五倍。这有效阻止了隔热材料中的热传导现象,即热量由热至冷的自然传导。保温容器能够防止过多热量向外部释放,而冰箱中的VIP则能够防止环境中的热量进入电器内部。二氧化硅实际上发挥着绝热体的作用,但同时也为隔热板提供保护,避免出现真空作用出现的凹陷。

**隔热材料

“芯材中二氧化硅结构的品质越好,VIP的隔热效果就越好,”赢创隔热应用技术部经理弗兰克•门泽尔(Frank Menzel)博士解释说。尽管VIP与传统隔热材料相比要薄得多,但是它能够达到约8至10倍的保温值。在实际应用中,这项性能意味着大幅减少能耗,同时增加冰箱内部的可利用空间。

因此,越来越多的冰箱组件供应商开始依靠AEROSIL®所带来的优异品质。其中一家供应商是Porextherm Dämmstoffe GmbH公司,它的总部设在肯普滕,十多年来一直从事VIP的生产。